Recently, the research group led by Dr. Qian Guangfu from the team of Academician Wang Shuangfei at the School of Light Industry and Food Engineering of our university has achieved a new advance in the field of the wood fiber carbon-based electrocatalyst. The related research findings have been published in Advanced Materials under the title "MoO₂‐Mediated Ni-Fe Bond Contraction and Electronic Modulation in Ni₃Fe Alloy for Efficient Water Electrolysis at High‐Current‐Densities". Li Liancen and Xu Haotian, master's students from the School of Light Industry and Food Engineering of our university, are the co-first authors of the paper. Assistant Professor Qian Guangfu is the corresponding author. Postdoctoral Fellow Chen Jinli from Huazhong University of Science and Technology and Professor Panagiotis Tsiakaras from the University of Thessaly, Greece, are the co-corresponding authors. Guangxi University is the primary affiliation.

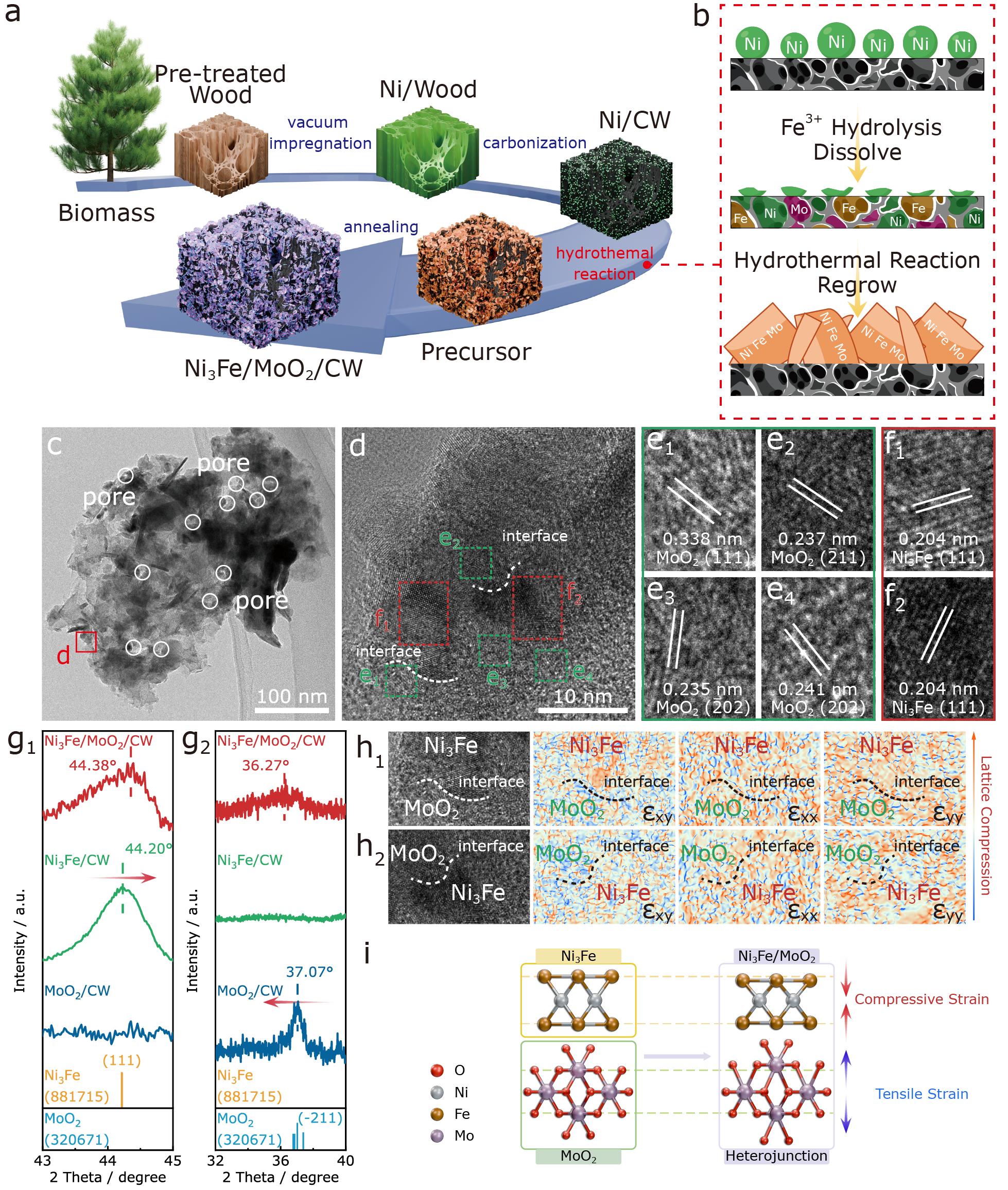

Hydrogen production via water electrolysis is considered a crucial pathway for achieving the green energy transition. However, under industrial high-current-densities, non-precious metal catalysts often face challenges such as sluggish hydrogen/oxygen evolution reaction (HET/OER) kinetics and inefficient gas-liquid mass transfer. To address these issues, the research group utilized the advantages of wood fiber to construct a 3D carbonized wood-loaded Ni₃Fe-MoO₂ (Ni₃Fe/MoO₂/CW) heterojunction catalyst. By introducing MoO₂, they induced Ni–Fe bond contraction and facilitated interfacial electron transfer, thereby optimizing the electronic structure of the catalyst and the adsorption behavior of reaction intermediates, significantly enhancing the reaction kinetics, and achieving outstanding activity and durability. Experiments demonstrated that this catalyst requires overpotentials of only 45 mV and 251 mV to drive current densities of 10 mA cm⁻² for the HER and 300 mA cm⁻² for the OER, respectively, in alkaline conditions. In an anion exchange membrane electrolyzer, it stably maintained a current density of 1000 mA cm⁻² at a voltage of 2.069 V for over 24 hours, demonstrating excellent potential for industrial application. This work also provides new insights for developing the efficient wood fiber carbon-based electrocatalyst and advancing the industrialization of green hydrogen energy.

It is reported that this research was supported by the Young Elite Scientists Sponsorship Program by CAST, the Guangxi Natural Science Foundation General Program, the Guangxi Natural Science Foundation for Young Scientists, and the Guangxi “Qingmiao” Talent Research Grant. The Key Laboratory of Clean Pulping and Papermaking and Pollution Control in Guangxi provided technical and resource support for the smooth progress of this study.

As a major forestry region, Guangxi Zhuang Autonomous Region (GZAR) is home to abundant timber resources. Given this resource advantage, achieving high-value utilization of lignocellulose has become an important research direction. This study utilized the framework of carbonized wood as a self-supporting substrate, which not only realized the high-value use of renewable biomass resources but also significantly enhanced the efficiency and stability of the electrocatalyst under high-current-density conditions. It opens a new pathway for applying Guangxi's characteristic biomass resources in the green hydrogen sector.